Table of Contents Show

An air compressor increases productivity as it allows many tools to run at once. With it, you can establish specialization of labor. This way, work is easier and faster.

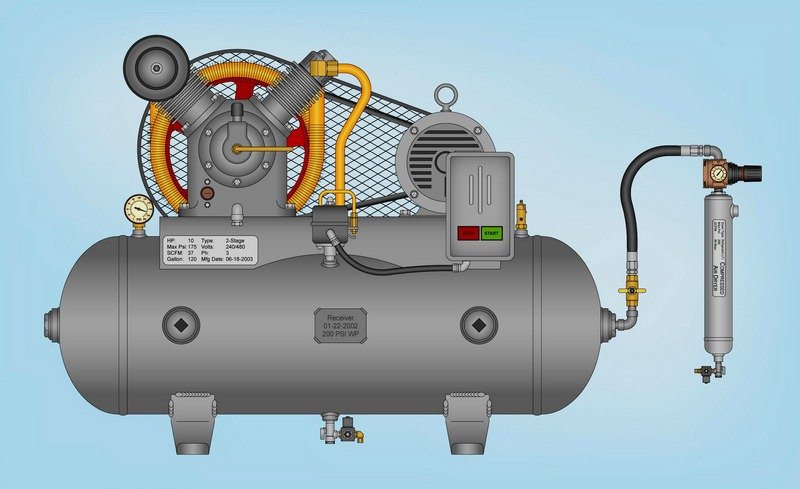

An air compressor works by converting the electricity from a motor to kinetic energy. Releasing bursts of high-density air will do the trick. For this, the air collects in a small space with pistons, vanes, or impellers.

High-density air bursts enable industrial work. If you get an air compressor for your business, you can do large scale production and you will be able to employ more workers and appoint tools for faster production.

Getting the Right Air Compressor

There are many tools that you can use with your air compressor. Some of them are air hammers, wrenches, socket ratchets, and drills. Other tools include brad nailers, pin nailers, and reciprocating saws.

Buying an air compressor is going to be expensive, so you have to get the right one for your business.

To do so, you have to match the requirements of your tools. In other words, compatibility is essential, or else, the whole investment is a loss.

Also, you have to consider the number of tools that are going to be running at the same time.

Examine the scale of your operation and consider any prospect of future expansion. As you see, getting an air compressor for your business is not that easy.

You can visit website if you want to get a good air compressor. You will find great air compressors for your business. The right one matches the requirements of your tools.

Size of the Air Compressor

The size of the air compressor should be based on the requirement of your business. Ask yourself: how much power do you need to run all the tools you need? If you have a small operation going on, then you can get a small, portable air compressor.

On the other hand, if you have a large operation, then get a large industrial size air compressor. This type of compressor is more efficient in terms of energy, meaning you will save more money in the long run.

However, portability has its advantages. Even though the small air compressor costs more in the long run, portability makes up for it.

You might need the power of the air compressor in different locations. A big air compressor will not give you this freedom, but a small one will.

Types of Air Compressors

There are quite a few types of air compressors available on the market. Some of them include a reciprocating, compound, rotary, scroll, and turbo compressors. The compressors vary in terms of principal and design of operation.

Oil-Free Air Compressors

This type of air compressor is cost-effective and light. Furthermore, you don’t need that much maintenance for it.

We recommend that you get an air compressor that is oil-free because it is safer for both the environment and the health of your workers.

The oil free air compressors produce oil-free air, and the quality of air is outstanding, so it helps maintain an emission-free environment.

Air quality is very important for your business, so buying an oil-free air compressor is a good idea.

There are some disadvantages of oil-free air compressors, though. The compressor is not as powerful as oil-lubricated air compressors, meaning it won’t last as long, so it’s appropriate for small operations.

If you have a huge operation or job to do, then this is not the air compressor for you. You should get an oil-lubricated air compressor for long and heavy-duty work.

Rotary Air Compressor

The rotary air compressor is efficient. With it, you can get back expending energy. Also, the machine is not noisy like other air compressors. And it does not make the air run at high temperatures.

It runs much longer than the oil-free air compressor, and it costs more too. The rotary air compressor is complex in design, so a lot of maintenance work goes into keeping it running.

However, because of the high horsepower, this is the most common compressor for industrial use.

Reciprocating Air Compressor

This type of air compressor does positive displacement, meaning that the air collects in a concealed enclosure. Next, a reciprocating piston compresses the air.

Positive displacement compression means it sucks in the air to make it dense by reducing the space.

The difference between a reciprocating compressor and a rotary compressor is simple. The rotary compressor utilizes an impeller in a rotary motion to make air dense.

On the other hand, a reciprocating compressor does the job with a piston-cylinder. In this case, upward movement compresses air.

Centrifugal Air Compressor

This type of air compressor is a turbocompressor that has a radial design. The machine sucks air to the rotating impeller that has radial blades.

Then, the air rushes towards the center because of the centrifugal force. Radial movement results in high pressure which in turn produces kinetic energy

The centrifugal air compressor is easy to manufacture because the design is easy. The advantage of having it is a high-pressure level for good combustion in a single-stage.

Conclusion

Air compressors are a really important part of manufacturing goods. You can use it to power all the tools you have that are necessary for production.

You will be able to run all of your tools all at the same time. This means that you can boost your efficiency tenfold or more depending on your labor force.

When you have an air compressor at your disposal and a lot of workers, specialize in your labor. Give everyone a simple task to do using tools so that they learn from repetition.

They will master their tasks and produce perfection, and the overall team will function more fluently.

When you are choosing the right air compressor, you have to consider how much power you need for production. If your operation is small, a small, portable air compressor might do the trick.

On the other hand, if you have a big operation to overlook, get your team an industrial-sized air compressor.

There are quite a few types of air compressors. A small operation needs an oil-free air compressor, but if there are many tools and a lot of work, pick a rotary lubricated compressor.

There are many types of air compressors to pick from. A rotary air compressor is the most common type. Others include the reciprocating air compressor and centrifugal air compressor.

When picking your air compressor, remember to match the requirements of your tools with those available in different air compressors.

Consider the workload and duration of work. It’s always best to buy an air compressor with a slightly higher capacity than your requirements.