Table of Contents Show

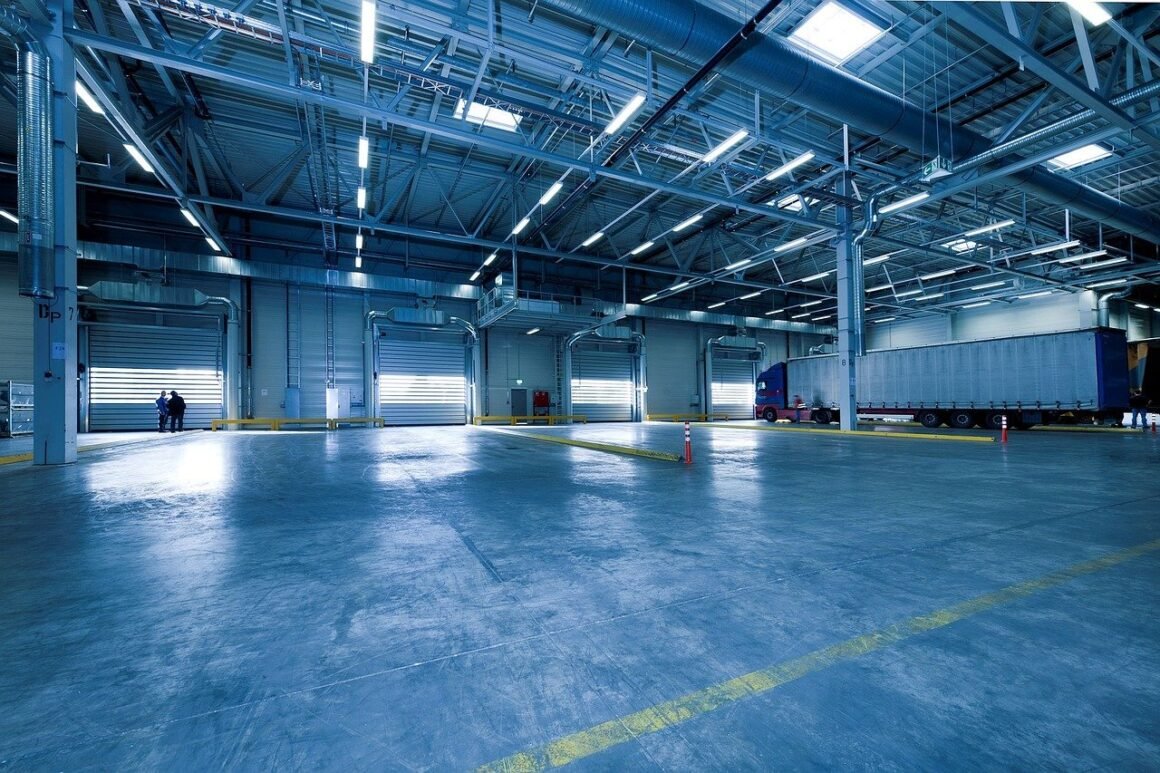

When big companies buy goods in large quantities for sale or distribution, these goods are usually stored in a secured facility called the warehouse.

The process of storing these goods that will be sold or distributed is called warehousing.

According to https://www.familymovers.com/warehouse-storage/, A warehouse is a storage room or space where goods are kept for some time. Warehouses are mostly targeted at large-scale businesses.

This is because small-scale businesses generally don’t have many goods to store. A garage, basement, or even a spacious room is usually enough to store their goods.

The Importance of Warehousing

Businesses into importation and exportation need to use a warehouse for safety. Warehousing gives you easy access and control over your goods, thereby ensuring that your customers get their orders promptly.

Warehousing also helps you keep everything organized. This will help you save money and also boost your productivity.

Here is some other importance of warehousing:

It Helps Reduce the Risk for Your Products

Since most warehouses are insured, this helps to mitigate certain storage-related risks.

For example, if your products get stolen or damaged while still in a warehouse, you may get compensated by the insurance company.

Warehouses are a perfect place to keep goods that require a certain temperature for preservation.

In case you are looking for where to store cold temperature-dependent items, cold storage in British Columbia can help you with this.

It Adds Value to Your Business

One of the advantages of warehousing is that your goods are delivered on time, and the distribution of your products is prompt.

This increases your customer satisfaction, as well as your workforce productivity. With warehousing, errors are reduced, and it also helps prevent damage to your goods.

Your goods are also protected and can’t be easily stolen or lost during your order fulfillment process.

This automatically increases your brand value and how your customers perceive your brand.

Read Also:

Fulfill Your Orders Efficiently

Warehousing allows you to store up your goods easily, ship them, and distribute them to your customers irrespective of their location.

With warehousing, tracking your goods and managing your inventory becomes easy and efficient.

It also helps you put down transportation costs and increases your flexibility.

Warehousing Processing

The warehousing process entails all that has to do with storing up and getting the goods to the buyers.

This process is dependent on the type of warehouse, the size of the warehouse operation, the company culture, the durability of the products, the temperature of the products, the volume of goods involved, and if there are any applicable legislative requirements.

Warehousing processing has five key processes which are common to all forms of warehousing operation, and they are:

The arrival of the Products

Receiving products into the warehouse is the first step in warehousing processing, and it is one of the most important processes.

It goes beyond just collecting goods for warehousing, as it involves a lot of activities. There will be a major impact on the whole process of warehousing if there is any disruption with receiving the products.

When goods arrive, they are checked properly with the supplier’s packing document. Once this is settled, they are inspected for any damage that might have occurred during the arrival process.

If any physical damage is recorded, all the goods in the shipment will be thoroughly investigated. Once the inspection is complete, the products are moved to the put-away area.

Storing of the Products

The goods are stored in the put-away area until it’s time for pick up. The process of moving the goods from the collection point to the storage point is also crucial.

It involves calculating available space and the resources required for the effective storage of each item. Similar goods are stored together for easy location and distribution.

Picking

This process deals with collecting items from the warehouse for shipment. This stage requires a lot of manpower and resources. It is also the most expensive step in warehousing.

Packing the Products

Packing involves collecting all the items listed in the sales order and putting them together for shipment.

The items are packed in suitable containers. They are weighed and labeled accordingly. The packed orders are now given to the right courier service for delivery.

Shipping the Products

This is the last stage in the process of warehousing. This is the process of dispatching goods according to the sales orders.

An arrangement is made with the carrier for the pick-up, and the whole process of shipping is made to align with the carrier pick-up times.

To ensure fast delivery, it is best to send out the goods on time.