Table of Contents Show

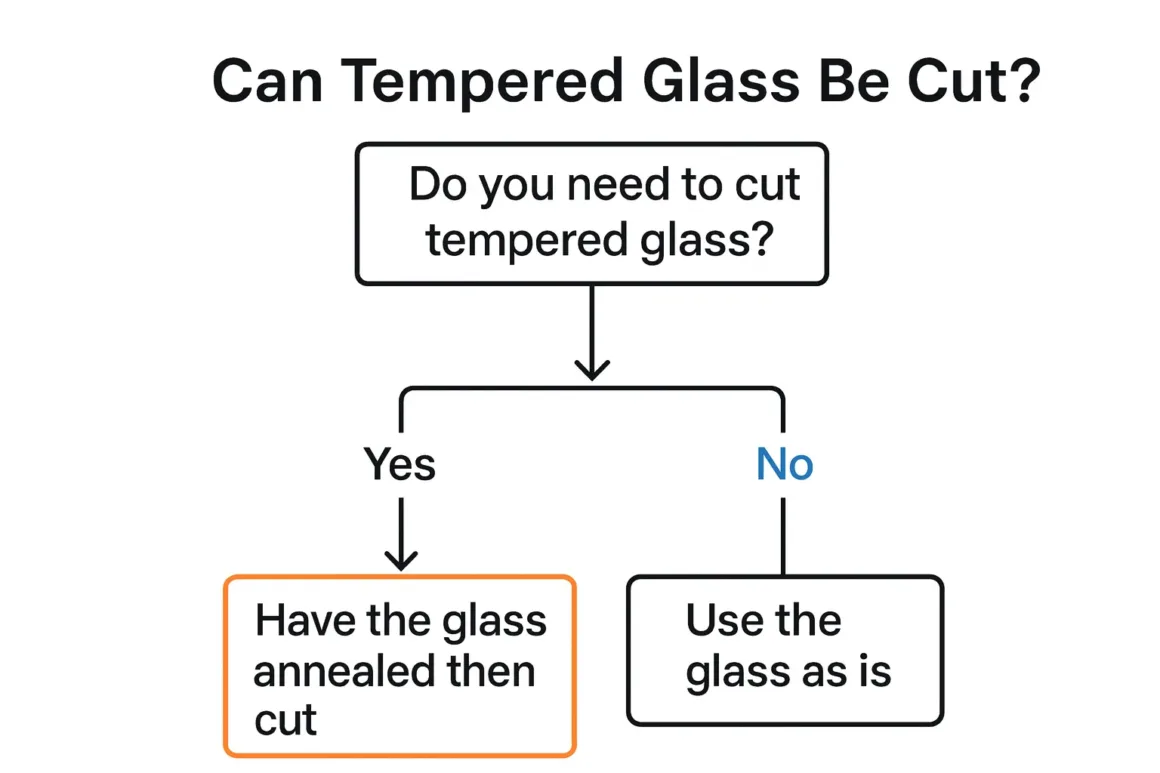

If you’re searching how to cut tempered glass, here’s the truth: you can’t cut or drill an already-tempered panel without a high risk of shattering. This guide explains safe, pro-approved alternatives, the rare salvage limits a fabricator might attempt, and when a full remake is the right, code-compliant path.

Safety disclaimer: This guide is for information only. Cutting, drilling, or notching already-tempered glass is dangerous and almost always ends in shattering. Follow local building codes and consult licensed professionals.

Key Takeaways (Read First)

- You cannot cut tempered glass after tempering. All size changes, holes, notches, and edge work must be done before the heat-treating step that creates the surface compression layer. See ASTM C1048 and Vitro TD-138.

- DIY workarounds with grinders or diamond blades are unsafe. On fully tempered glass, any deep grinding or cutting destabilizes the compression layer and can cause explosive failure. See NGA/GANA — Edge Grinding and Guardian — Technical Guidelines.

- A narrow, pro-only exception exists: In rare cases, a tempering/fabrication shop may attempt to remove a very small amount (often ≈1/8″ per edge) to rescue a slightly oversized lite—not guaranteed and not DIY. See industry discussion at Dillmeier Glass.

- Safe alternatives win the job:

- Order a new lite cut to size and then tempered.

- Cut annealed glass first via waterjet/laser, then temper (see Vitro TD-124).

- Use laminated safety glass where code allows.

- For non-code applications, consider acrylic or polycarbonate.

Why Tempered Glass Shatters When You Try to Cut It

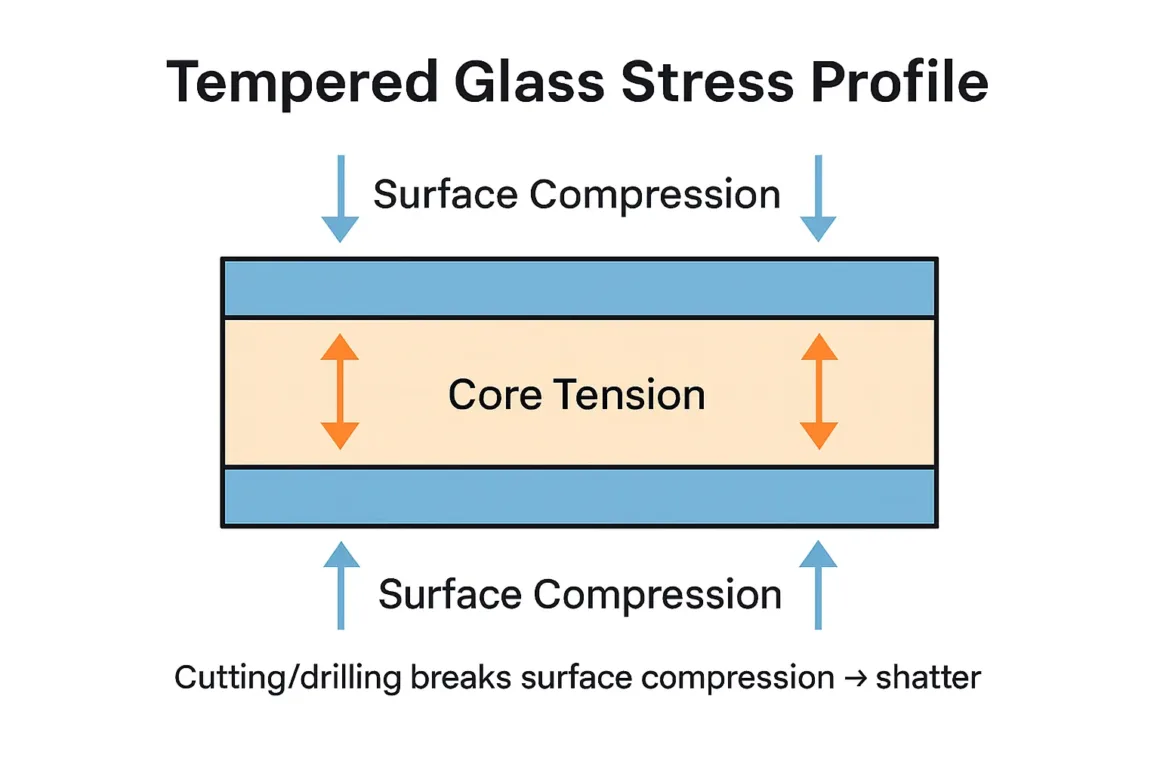

Tempered (toughened) glass is heated and rapidly quenched to create compressive stress at the surface and tensile stress in the core. This stored energy is what makes it strong—and what makes it fail in a controlled, “dice-like” pattern. Any post-tempering cut, drill, or deep grind breaks the surface compression layer, releasing energy and causing the panel to shatter into pellets. See ASTM C1048 and fabrication cautions in Vitro TD-138.

Bottom line: The physics are against you. There is no special “tempered glass cutter” that bypasses this.

Safe Alternatives When You Need to “Cut” Tempered Glass

1) Order a New Lite Cut to Size, Then Temper

This is the standard fix for shower doors, tabletops, shelves, and guards. Choose edges (seamed/flat-polished/pencil), specify thickness (e.g., 6 mm, 10 mm), and include all holes, notches, and cut-outs before tempering. Minimum distances from edges and hole sizes are detailed in trade manuals like the NGA Heavy Glass Door Design Manual.

Pro tip: Provide hardware specs (hinges, standoffs, clamps) up front—hole diameters and locations must meet the fabricator’s minimums (see Vitro TD-124).

2) Fabricate in Annealed First, Then Temper

If your shape is custom, a shop can waterjet or laser-cut annealed glass to your drawing, finish the edges, and then temper the final shape. This is a professional workflow (see process guidance in Vitro TD-138), not a garage project.

3) Laminated or Acrylic: When They’re Better Choices

Laminated glass (two sheets bonded by an interlayer) provides safety without relying solely on tempering. It can often be cut and edged by a pro shop to custom sizes, then heat-treated if required by code. For fundamentals, see Pilkington — General Glazing Guidelines.

4) Choose Acrylic/Polycarbonate for DIY-Friendly Cutting

For desk protectors, picture frames, and light-duty covers, acrylic or polycarbonate can be cut with woodworking tools and the right blades. See our primer on plexiglass strength & properties.

Myth Busting (and Targeted Answers to Popular Queries)

“How to cut tempered glass at home?”

You don’t. Home methods (score-and-snap, angle grinder, tile saw) almost always end in shattering. See ASTM C1048 and Guardian — Technical Guidelines.

“Cutting tempered glass with a grinder or diamond blade?”

These tools are appropriate for pre-tempering fabrication or controlled edge finishing at the factory—not for resizing finished tempered glass. See NGA/GANA — Edge Grinding and Vitro TD-124.

“Tempered glass cutter” or “by hand” with a wheel-type glass cutter?

Score-and-snap only works on annealed glass. There is no consumer cutter that can resize tempered glass. See ASTM C1048.

“How to cut a tempered glass shelf?”

Order a new shelf to the correct size, or have a shop cut the shape in annealed glass and then temper. Don’t attempt to trim an existing tempered shelf (see Guardian — Technical Guidelines).

“How to cut a tempered glass screen protector without breaking it?”

Tempered protectors are thin yet still tempered—trimming usually cracks them. Buy the correct size, or switch to a film (non-glass) protector that can be trimmed. Background: post-temper cutting is not permitted under ASTM C1048 principles and manufacturer guidance like Vitro TD-138.

Identify What You Have (Tempered vs. Not)

- Bug stamp: Look in a corner for a tempering/safety mark (ANSI/EN).

- Polarization pattern: Through polarized sunglasses or a phone with a polarized filter, tempered glass often shows light/dark stress patterns.

- Break pattern (do not test): Tempered breaks into small pellets; annealed breaks into long, sharp shards.

If you’re unsure, assume it’s tempered—especially for doors, guards, shower enclosures, and any glazing labeled “safety.” For fundamentals, see Saint-Gobain — Toughened Glass (“after toughening, glass can neither be cut, nor altered”).

Copy/Paste: Spec Checklist to Send Your Glass Shop

- Overall W × H and thickness (e.g., 24 in × 36 in × 3/8″ or 610 mm × 914 mm × 10 mm)

- Edge finish: seamed / flat-polished / pencil-polished

- Holes: diameters, center-to-edge distances, and locations

- Notches/cut-outs: include radiused corners and detailed dimensions

- Temper level: fully tempered or heat-strengthened; any ceramic frit/band requirements

- Application & code context: shower, guard, tabletop, railing, etc.

- Hardware schedule: hinges, clamps, standoffs, grommets, fasteners

(For edge and hole spacing principles, see NGA Heavy Glass Door Design Manual and Vitro TD-124.)

When to Call a Professional (and What to Ask)

Call a glazier or local fabrication shop if:

- Your panel is already tempered and the size is wrong

- You need holes/notches for hardware

- A shelf doesn’t fit its brackets

- You can’t confirm if a lite is annealed vs. tempered

What to ask: “Can you remake this lite with all fabrication completed before tempering?” Some shops may attempt a tiny edge reduction (~1/8″ per edge) under controlled conditions—no guarantees and not a homeowner task (see Dillmeier Glass).

Safe Alternatives, By Use Case

- Tabletop/desk cover: New tempered to size or laminated safety glass; acrylic for light-duty scratch-tolerant use

- Shower door/panel: New tempered to spec with all holes/notches in the drawing (see NGA Heavy Glass Door Design Manual)

- Shelving: New tempered (commonly 6–10 mm) with polished edges and bracket holes defined up front

- Guards/railings: Follow engineer/shop drawings; many systems require tempered-laminated units

- Small device protectors: Buy the correct size or use a film protector you can trim

Internal Resources to Keep Reading

Frequently Asked Questions

Can you cut tempered glass without breaking it?

Can I use a grinder or diamond blade to cut tempered glass?

What are safe alternatives to resizing tempered glass?

Can a shop ever trim a tempered pane?

Reviewed by

Mark Meshulam — Building Façade & Glass Consultant; Expert Witness; 40+ years in architectural glass and glazing.

Credentials: Former façade contractor & engineering leader; principal at Mark Meshulam LLC; publications on tempered/heat-treated glass, failure analysis, and safety glazing; consultant to architects, contractors, and insurers.

Profile: chicagowindowexpert.com

- ASTM C1048 — Standard Specification for Heat-Treated Flat Glass (ASTM International)

https://www.astm.org/c1048-18.html - NGA / GANA — Technical Paper: “Edge Grinding”

https://www.glass.org/…/Edge%20Grinding…pdf - NGA — Heavy Glass Door Design Manual

https://www.glass.org/…/Heavy%20Glass%20Door%20Design%20Manual_2021.pdf - Vitro — TD-138: Heat-Treated Glass for Architectural Glazing

https://www.vitroglazings.com/…/vitro-td-138-heat-treated-glass-v9.pdf - Vitro — TD-124: Fabrication of Heat-Treated Glass

https://www.vitroglazings.com/media/rocj2kmu/vitro-td-124.pdf - Guardian Glass — Technical Guidelines

https://static1.squarespace.com/…/Guardian%2BGlass%2BTechnical%2BGuidelines.pdf - Pilkington (NSG Group) — General Glazing Guidelines (ATS-192)

https://www.pilkington.com/…/ats192generalglazingguidelines2013102.pdf - Saint-Gobain Glass — Knowledge Center (Toughened/Tempered Glass)

https://in.saint-gobain-glass.com/knowledge-center/toughened-glass

Final CTA

Need a code-compliant solution? Contact a local glazier or fabrication shop with the Spec Checklist above and ask for a remake with all fabrication completed before tempering.

Last updated: October 10, 2025