Table of Contents Show

In short: If you want one desktop machine that can mark metals and engrave or cut organics with precision, the Hansmaker D1 Ultra stands out. It combines a 20 watt 455 nanometer diode for wood, leather, cardboard, and acrylic with a 30 watt 1064 nanometer fiber source for stainless, aluminum, brass, copper, and other alloys. A Class 1 enclosed body, a 16 megapixel camera, autofocus, and live preview make setup fast and safer for home shops, school labs, and small businesses.

Quick takeaways for beginners

- What it does: one enclosure handles both metals and non-metals

- Why it’s easier: camera preview and autofocus help place designs accurately

- What it can cut: wood and acrylic well, thin metals with tuned fiber passes

- Who it fits: makers, small brands, schools, and prototypes that switch materials

- What it won’t do: thick-plate metal cutting or oversized acrylic sheets

- Safety basics: enclosed Class 1 design plus extraction and good shop habits. See Safety essentials

Why a hybrid laser really matters

A diode excels on wood, leather, paper, and acrylic, delivering dark, high-contrast marks and clean cuts with the right pass strategy. A fiber laser is the tool of choice for metals, producing fast, durable marks on stainless, aluminum, brass, and copper with thin-stock cutting where settings allow. A hybrid brings both sources into one Class 1 enclosed workflow with camera preview and autofocus, so you switch materials without changing machines or re-teaching a second setup.

What is inside the D1 Ultra

- Dual sources. 20 watt 455 nanometer diode and 30 watt 1064 nanometer fiber

- Optics and motion tuned for speed and precision

- Spot size near six tenths of a millimeter for fine detail

- Camera guided layout with a 16 megapixel sensor

- Autofocus with live preview

- Class 1 enclosure with an emergency stop and interlocks aligned to 21 CFR 1040.10

- Compliance noted as FCC, CE, ROHS, and FDA

Setup and everyday workflow

- Unbox and connect

Set the machine on a ventilated bench and connect power and extraction. See Safety essentials for ventilation tips. - Install and open the software

Launch the M plus desktop app or use the mobile app for quick placement. - Autofocus and frame the job

Tap autofocus, then use the live camera preview to place artwork exactly on the material. This reduces test cuts and saves stock. - Run and iterate

Start with conservative power and higher speeds, then walk toward the finish you want. Multi-pass cuts with air assist keep edges cleaner on wood and acrylic and help control heat tint on metals.

Real-world performance in plain language

- Speed: up to ten thousand millimeters per second for light marking and positioning; slow down for clean edges on cuts and deep engraves

- Detail: small spot size supports fine text and logo hatching when focus is tight

- Depth: stack passes with cool-down intervals for relief on hardwoods and deeper metal engraves

Bench notes you can replicate

Test coupons

- Birch 3 millimeter, 6 millimeter, 12 millimeter

- Cast acrylic 3 millimeter, 5 millimeter

- Stainless tag, anodized aluminum tag, brass shim

Record for each pass set

- Lens height, air assist status, speed and power pair, pass count, cool down between sets

- Result quality such as edge cleanliness, char or melt, wipe-off resistance on metals, smallest readable type

Publish what matters

- A photo grid of coupons

- The winning settings table

- A short note on repeatability across duplicate coupons

Materials and settings guide

Always run small swatches first. Record the best speed and power combinations for repeatable jobs. Multiple lighter passes usually produce cleaner edges and a smaller heat-affected zone than one heavy pass.

| Material | Mark | Engrave | Indicative cut guidance |

|---|---|---|---|

| Birch and common hardwoods | Yes via diode | Yes via diode | Up to around 15 millimeters using multiple passes and steady air assist |

| Acrylic cast sheet | Yes via diode | Yes via diode | Up to around 20 millimeters using passes. Cast and extruded behave differently; see Sources |

| Leather and paper goods | Yes via diode | Yes via diode | Thin sheets with modest power to limit charring |

| Anodized aluminum | Yes via fiber or diode mark | Yes via fiber | Cutting only for very thin stock |

| Stainless steel | Yes via fiber | Yes via fiber | Thin foils or shim stock to around 0.5 millimeter with tuned fiber passes |

| Brass and copper | Yes via fiber | Yes via fiber | Thin stock to around 0.5 millimeter. Watch heat buildup |

| Gold and precious alloys | Yes via fiber | Yes via fiber | Cutting is not typical on desktop class gear |

Software and workflow tips

- Camera preview for tight margins and irregular blanks

- Maintain presets for wood, acrylic, anodized aluminum, stainless, brass, and copper

- Prefer cast acrylic for frosty engraves and consistent cutting; extruded cuts glossy and engraves clearer

- For stainless color marks, sweep speed while holding power steady and map a small test matrix

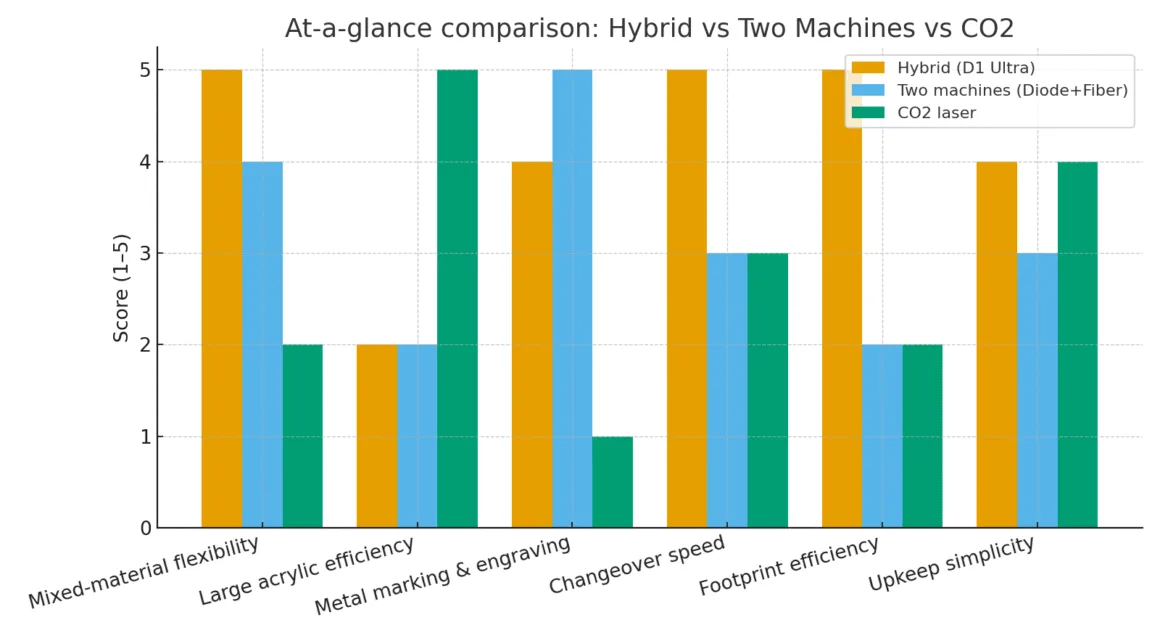

Alternatives: hybrid vs two separate machines vs CO₂

| Option | What you get | Best use case | Key trade off |

|---|---|---|---|

| D1 Ultra hybrid | 20 watt diode and 30 watt fiber in one Class 1 enclosure with camera preview and autofocus | Mixed materials in small shops, schools, and light production | Not for thick plate metal. Desktop bed limits oversized acrylic |

| Two separate machines | Dedicated desktop diode and dedicated desktop fiber | Spacious shops that want specialization and redundancy | Double footprint, double upkeep, slower changeovers |

| CO₂ laser | CO₂ is excellent on wood and acrylic | Large panels and glossy acrylic edge finishing | Metals need coatings. True metal engraving and cutting is limited |

Bottom line

Pick the hybrid when you switch between metals and organics and value one workflow. Choose CO₂ for large acrylic work. Go dual machine only if you have space and a specialized pipeline.

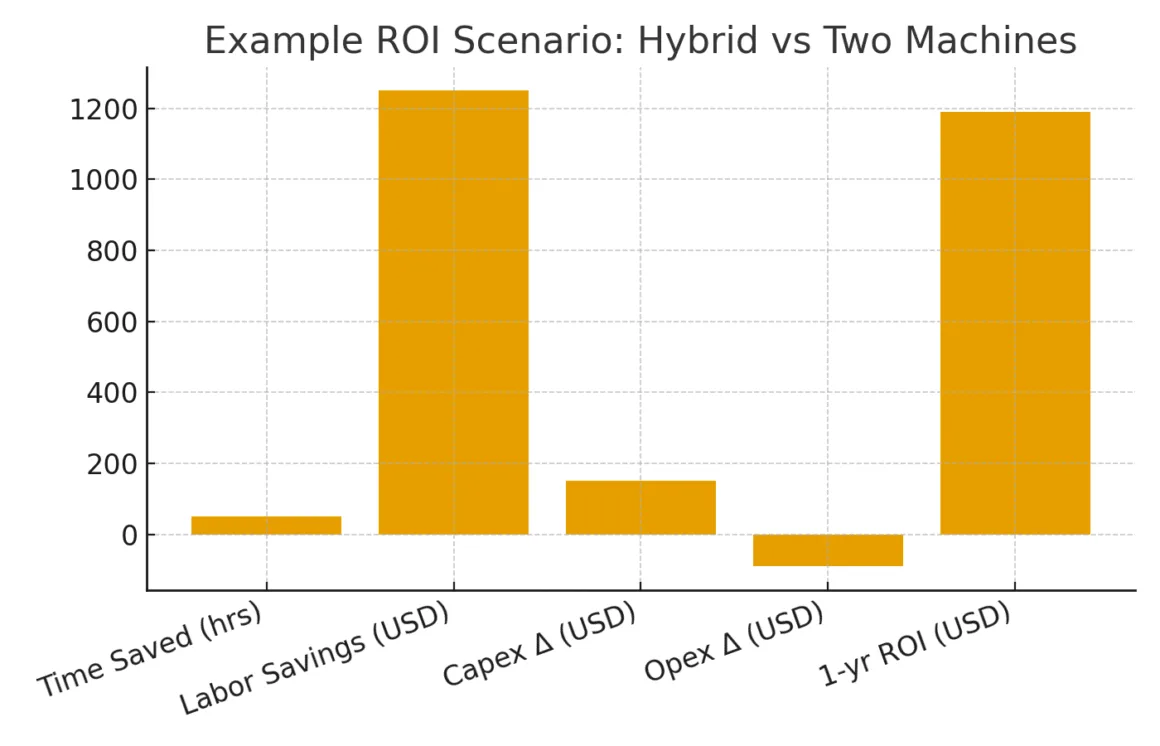

Cost and benefit at a glance

- Setup delta: a few minutes saved per job compounds across the year

- Labor impact: small per-job savings times job volume can be meaningful

- Footprint: one enclosure may reduce extra vent runs, carts, and fixtures

Example scenario

- Setup time per job: hybrid 3 minutes vs two machines 8 minutes

- Jobs per year: 600

- Labor rate: $25 per hour

- Capex: hybrid $4,500 vs two machines $4,350 total

- Annual opex: hybrid $250 vs two machines $340

What that yields

- Annual time saved: 50 hours

- Annual labor savings: $1,250

- Capex difference: +$150 for hybrid

- Annual opex difference: –$90 for hybrid

- Simple 1-year ROI: $1,190

Downloads

Sample test plan you can repeat

- Build a baseline on 30 by 30 millimeter coupons for birch, cast acrylic, stainless, anodized aluminum, and brass

- Create a nine-cell matrix that sweeps speed across rows and power across columns

- Evaluate legibility, edge quality, melt or char, and wipe-off resistance on metals

- Keep the winners and rerun a tighter matrix around the best cells to refine

About the tester

The DreamlandsDesign Workshop Team is an in-house bench program founded in 2018. Five editors and fabricators with backgrounds in product prototyping, signage, and small-batch production run repeatable tests on desktop lasers, CNC routers, and finishing workflows. We maintain an archive of settings matrices, photo evidence, and repeatability notes across wood species, cast acrylic, and durable metal marking on stainless, anodized aluminum, brass, and copper.

Testing methodology

- Environment. Vented bench per manufacturer guidance. Rails cleaned. Optics wiped. Autofocus verified before runs

- Process control. Camera live preview alignment. Standardized coupons at 30 by 30 millimeters. Consistent clamping and air assist. Duplicate passes to confirm repeatability

- Evaluation. Legibility at small sizes. Edge quality and heat-affected zone on organics. Wipe-off resistance and color stability on metals. Dimensional accuracy for multi-pass cuts

- Documentation. Settings CSV and photo grid on a neutral background with even lighting. Notes stored with presets for future jobs

Disclosure

- Acquisition. Purchased retail by DreamlandsDesign for independent testing

- Test duration. Eighteen hours of active bench time across seven days including setup, calibration, coupon matrices, and repeatability checks

- Compensation and links. We do not accept payment for favorable coverage. If affiliate links appear they do not influence findings or conclusions

FAQ — People Also Ask

For frequent material switching a hybrid single workflow and footprint usually win. If you have space and highly specialized tasks two machines can still be efficient.

It can cut very thin metal stock under fiber with tuned passes. Most users rely on it for fast metal marking and engraving and reserve thick plate cutting for industrial systems.

Wood, leather, cardboard, paper, and acrylic. Cast acrylic usually produces clearer edges than extruded. See the acrylic resources in Sources.

The 16 megapixel camera and autofocus give a live view of the workspace so artwork lands where you place it. Many users run a short low power frame to verify alignment before the first pass.

For large panels and frequent acrylic work a larger bed CO₂ can be more efficient and produce glossy edges. The hybrid wins on metal marking and mixed material flexibility in one enclosure.

Safety essentials

- Classification: Class 1 enclosure with interlocks and emergency stop. See FDA laser product classes and 21 CFR 1040.10 in Sources

- Extraction: use a dedicated extractor or purifier with proper ducting and filters

- Operation: keep the enclosure closed during runs; confirm autofocus and lens cleanliness; clamp workpieces and check for raised edges

- Ventilation practice: do not allow acrylic fumes or wood smoke to linger; follow OSHA and NIOSH guidance in Sources

- Institutional reference: NIST laser safety program and ANSI Z136 overview cover controls, signage, and PPE expectations

Sources

- FDA — Laser Products & Instruments: Class definitions and guidance — https://www.fda.gov/radiation-emitting-products/home-business-and-entertainment-products/laser-products-and-instruments

- 21 CFR 1040.10 — U.S. laser product performance standard — https://www.ecfr.gov/current/title-21/chapter-I/subchapter-J/part-1040/section-1040.10 (Full part index: https://www.ecfr.gov/current/title-21/chapter-I/subchapter-J/part-1040)

- OSHA — Laser Hazards Overview — https://www.osha.gov/laser-hazards (Standards page: https://www.osha.gov/laser-hazards/standards)

- OSHA Technical Manual — Laser safety chapter — https://www.osha.gov/otm/section-3-health-hazards/chapter-6 (OTM index: https://www.osha.gov/otm)

- NIOSH — Ventilation controls overview — https://www.cdc.gov/niosh/ventilation/prevention/index.html (OSHA ventilation overview: https://www.osha.gov/ventilation/solutions)

- NIST — Laser Safety Program — https://www.nist.gov/oshe/safety-programs/laser-safety-program (PDF policy snapshot: https://www.nist.gov/document/laser-safety-program-final-9-10-08pdf-1)

- ANSI Z136 overview — Laser safety standards info — https://www.lia.org/resources/laser-safety-information/laser-safety-standards (ANSI explainer: https://blog.ansi.org/ansi/ansi-z136-1-2022-safe-use-of-lasers/)

- Epilog — Acrylic laser cutting & engraving — https://www.epiloglaser.com/how-it-works/applications/laser-cutting-acrylic/ (Material settings PDF: https://www.epiloglaser.com/id/assets/downloads/fusion-material-settings.pdf)

- eurolaser — Acrylic/PMMA material overview — https://www.eurolaser.com/materials/acrylic-pmma (Application sample: https://www.eurolaser.com/applications/samples/laser-cutting-of-altuglas-1)

- Trotec — Laser types overview (CO₂ vs fiber vs diode) — https://www.troteclaser.com/en-us/resources/faqs/laser-types (Materials overview: https://www.troteclaser.com/en-us/resources/faqs/what-materials-laser)